Introduction: the early years and a major upgrade

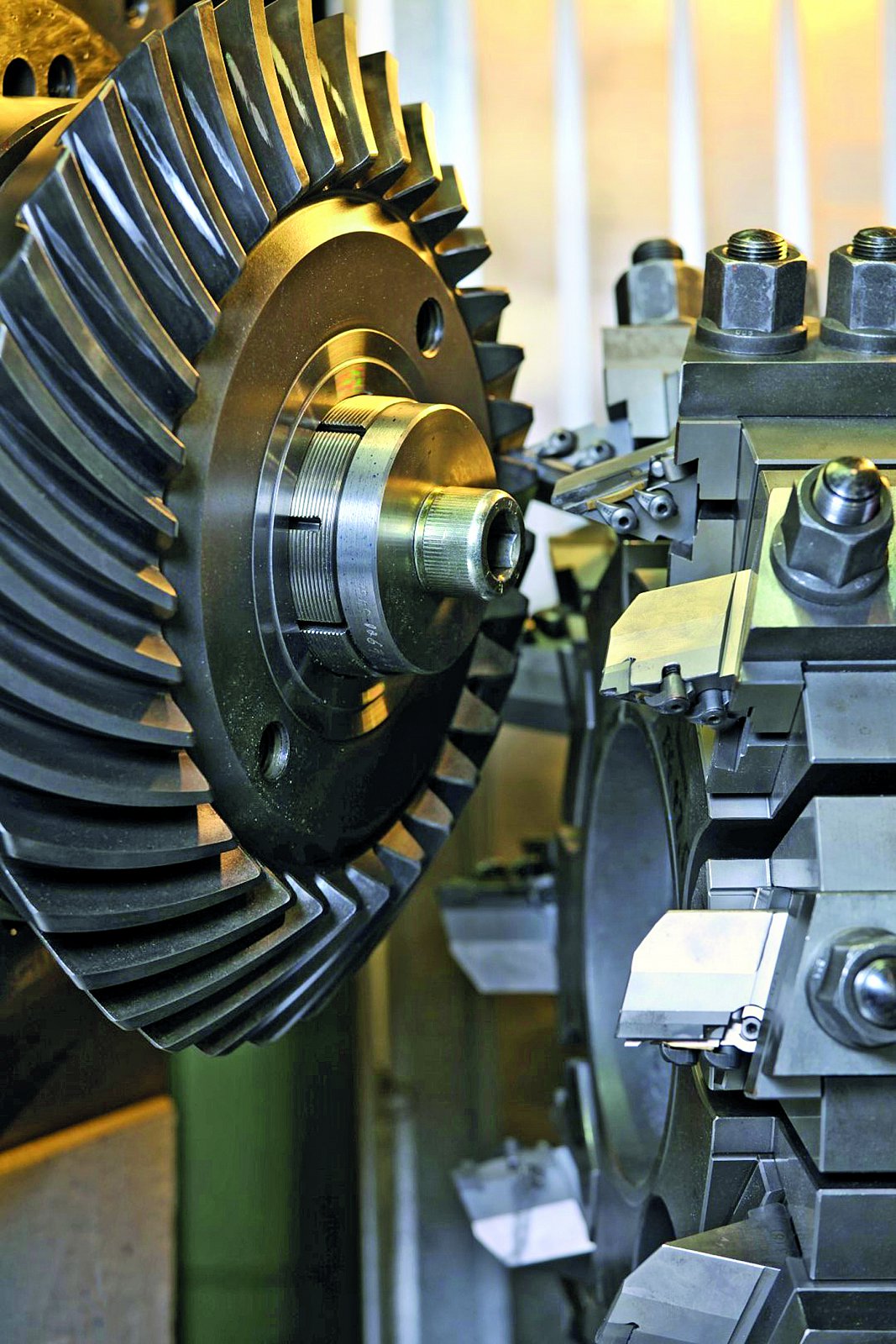

IGW first began using the QAD ERP system in 1999 when it was implemented in its Belgium-based plant. Since then, IGW gradually acquired a number of additional companies, each with their own processes and each using a different version of QAD ERP. In 2013, a decision was taken by the new group management to unify the processes across the expanding group which now comprised several plants with general mechanical engineering production capabilities as well as others focussed on manufacturing gears for the automotive industry. This was supported by upgrading each company to the Enterprise Edition of QAD ERP based on a common database and shared platform.

As a result, data could now be efficiently shared across the entire group which greatly facilitates all processes from order acquisition, product through to delivery. The upgraded QAD system also comprehensively covers each company‘s operations in the fields of production management, warehouse management, capacity planning (MRP), purchasing, accounting and finance, with data exchange between plants in the group as well as the supply chain now being handled by EDI. QAD support modules that facilitate integration of third-party applications, especially Qxtend that IGW uses to synchronize master data with its PLM system, were implemented at the same time.

QAD ERP Enterprise in operation

One of the major benefits of the QAD ERP Enterprise Edition is its „domain-based“ architecture which allows separate business entities, domains, to be held within a single database. IGW uses five domains to represent individual plants within the group as well as a master domain that works as a parent domain. This allows employees to share material availability and coordinate production activities as well as the flow of goods.

Product bills of material information for all companies in the group has been centralised which streamlines the sale process, dealing as it does with global contracts that stipulate which plant should produce and deliver particular goods according to local criteria as well as efficiency considerations. IGW manufactures standard and customised products, the latter including development and testing which can take approximately 8 to 12 months.

Ongoing developments and future plans

IGW has expanded its operations with the acquisition of a mechanical engineering company based in India into which it plans to introduce its unified EDI processes and other activities. The plant along with its 1600 employees will be primarily used within the group for assembly operations and will help expand its wider business activities.

„With the acquisition, we have found out that QAD ERP gives us a big advantage as it is a system that is globally available,” concludes Brenkus. He continues, “Wherever we need it, there are support and service organizations at hand, whether directly from QAD or within its partner network. Only few ERP systems on the market can offer such a service.“